VIGIFLAP

APPLICAZIONI

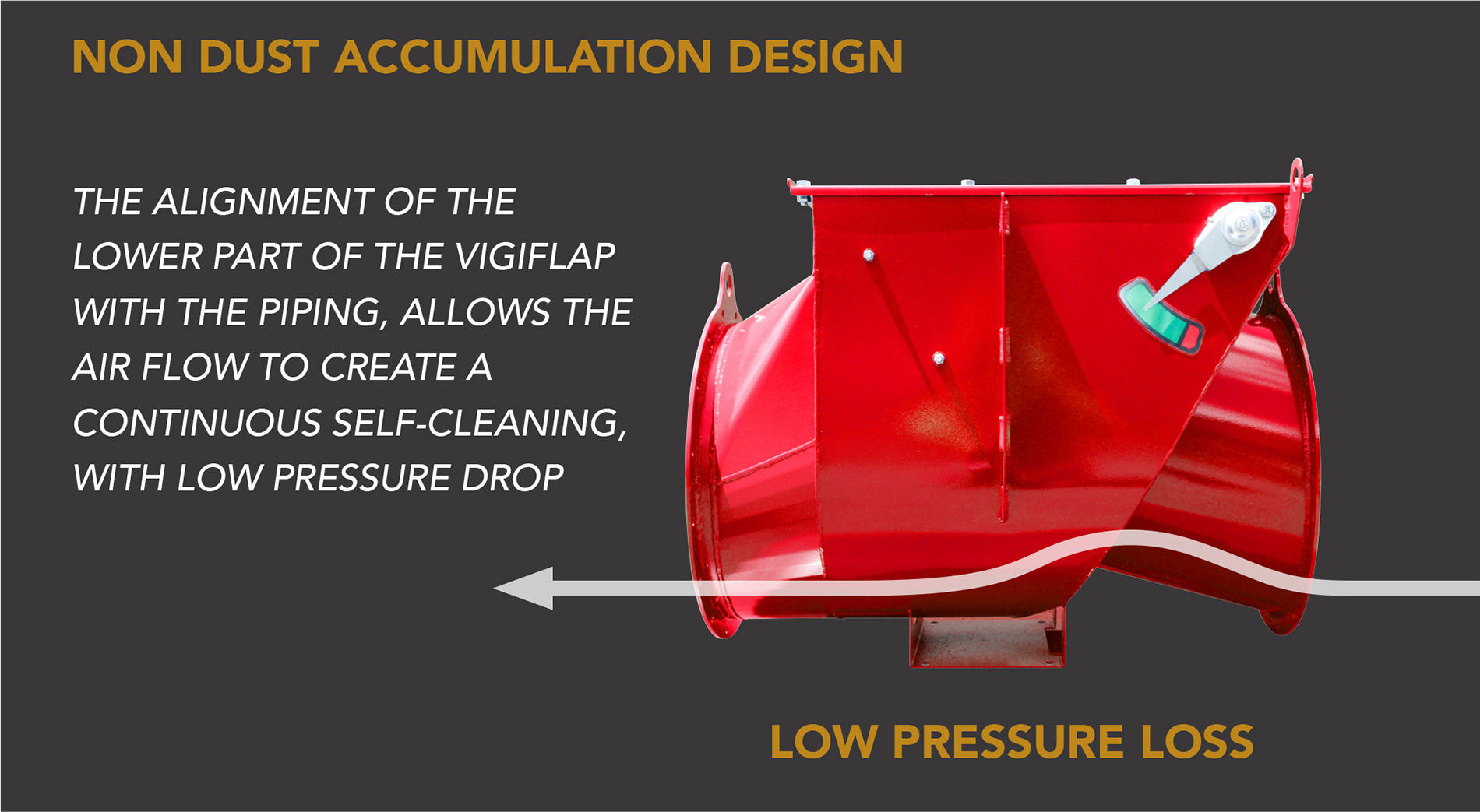

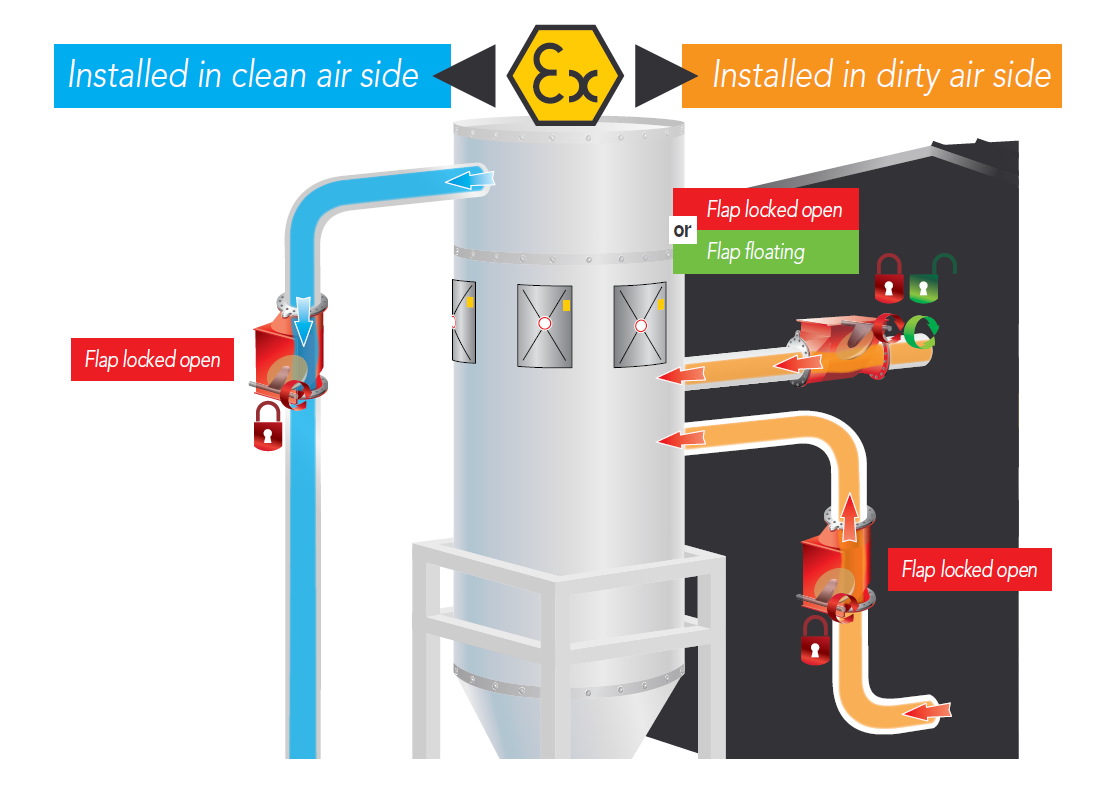

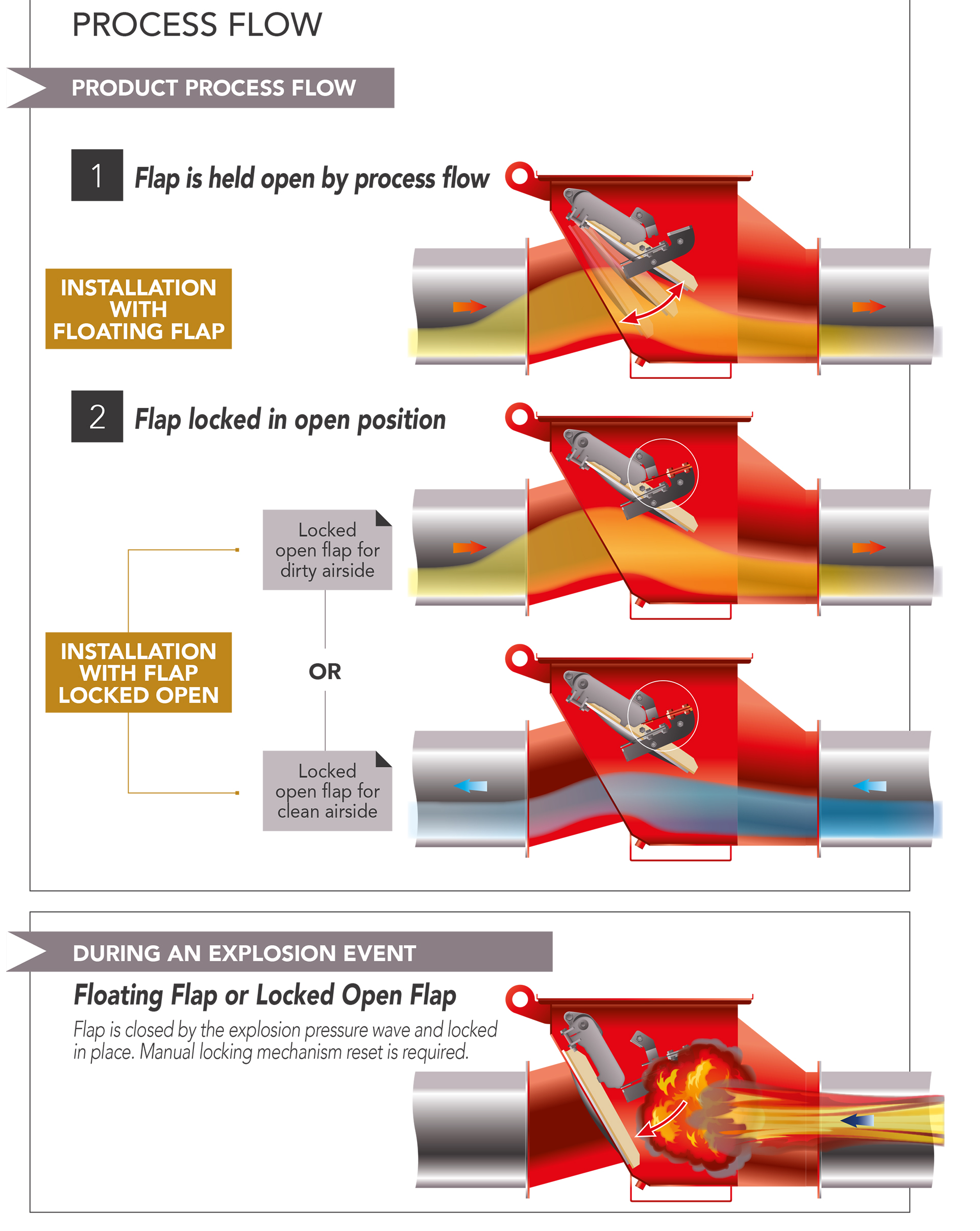

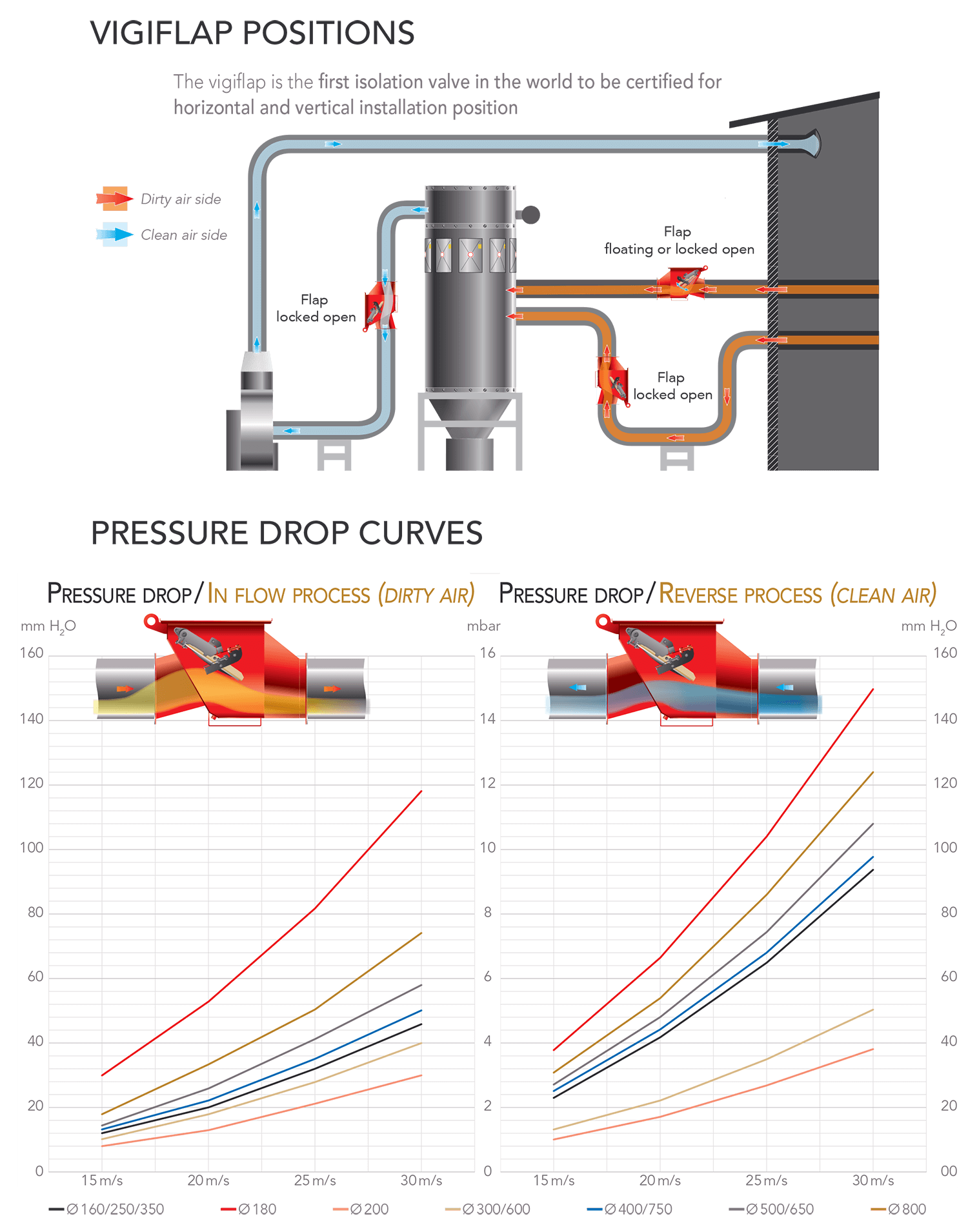

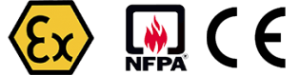

La VIGIFLAP è una valvola di non ritorno progettata per evitare che la sovrappressione o la fiamma provocata da un’esplosione a valle (depolveratori filtri, cicloni…) si propaghi nel sistema di tubazioni.La valvola è tenuta aperta da un braccio di leva. Può essere utilizzato sia all’ingresso che all’uscita del filtro. Ciò consente di isolare il filtro da un’esplosione o da una sovrappressione.In caso di esplosione la valvola si chiude e rimane bloccata impedendo l’avanzamento della fiamma. Lo sblocco dello sportello avviene manualmente.

Explosion Isolation valve

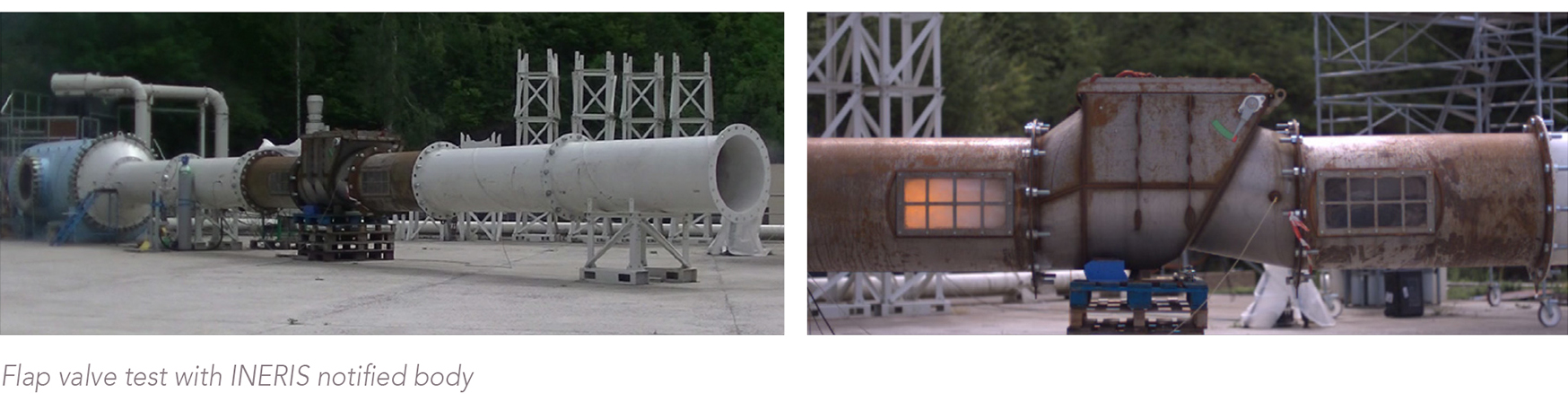

HIGH CERTIFICATION TEST

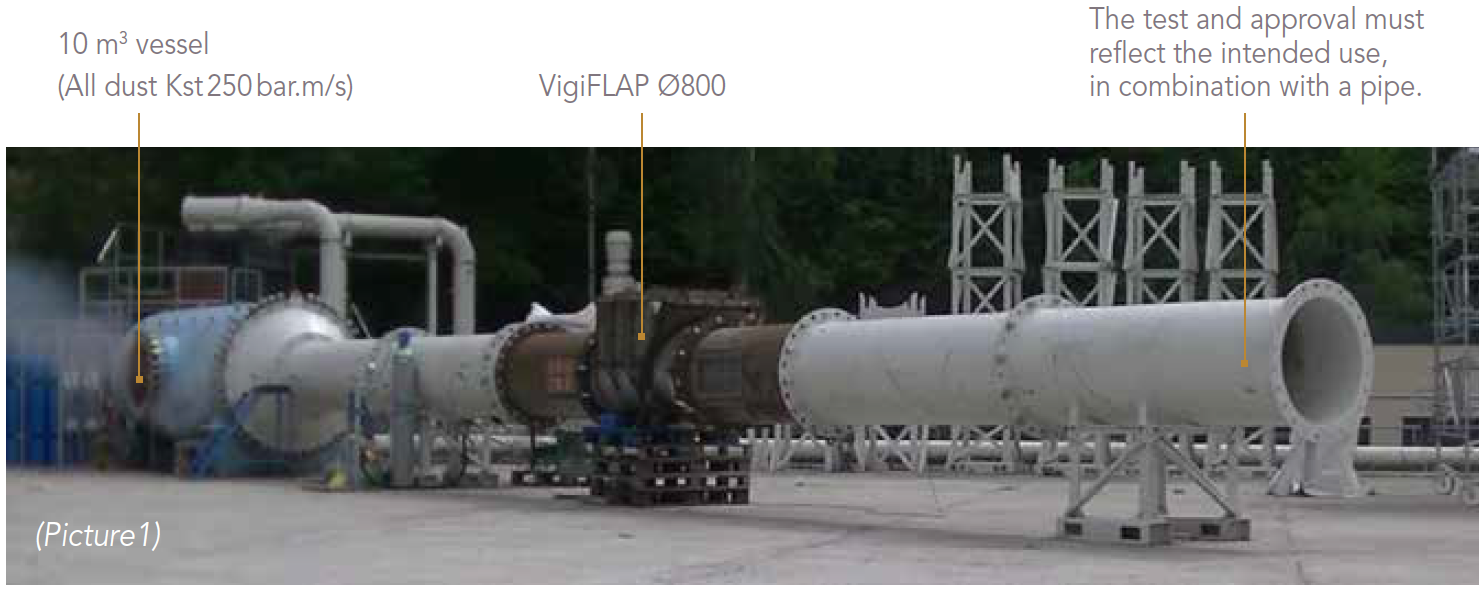

Per ottenere il nostro certificato Atex ( N° INERIS 19ATEX0016X) secondo la norma EN16447:2014,abbiamo effettuato i nostri test di esplosione nelle condizioni più estreme e il più vicino possibile alla realtà dell’uso del prodotto, come per esempio:

- Gasdotto Zona Protetta:

Tutti I test sono effettuati su una tubazione posta dopo la valvola (foto1). - Battente bloccato aperto:

Rilascio automatico della valvola causato dalla pressione dell’esplosione. - Battente flottante:

Durante il test la valvola viene tenuta completamente aperta fino al momento opportuno di rilascio. - Pannello di sfiato nell’ambiente/recipiente di prova:

Durante il test non sono state utilizzate porte aperte , ma sono sempre stati utilizzati pannelli di ventilazione.

IL FUTURO:

Tra pochi mesi le certificazioni ATEX di VIGIFLAP saranno ulteriormente incrementate con le seguenti caratteristiche aggiuntive :

- Dimensioni fino al diametro 1370 mm

- ST3

| DN (mm) | DN (inch) | Minimum Vessel Volume | LMin* Min Mounting Distance | LMin** Min Mounting Distance | L Max Max Mounting Distance | Download PDF (mm) | Download PDF (inch) | |

|---|---|---|---|---|---|---|---|---|

| DN (mm) | DN (inch) | Volume minimal | LMin * Distance de montage minimale | L Min+2m** Distance de montage minimale | L Max Distance de montage maximale | Télécharger PDF (mm) | Télécharger PDF (inch) | |

| DN (mm) | DN (Pulgadas) | Volumen minimo del recinto | LMin* Distancia mínima de montaje | L Min+2m** Distancia mínima de montaje | L Max Distancia máxima de montaje | Descargar PDF (mm) | Descargar PDF (Pulgadas) | |

| DN (mm) | DN (inch) | Min. Volumen | L Min * Min. Montageabstand | L Min+2m ** Min. Montageabstand | L Max Max. Montageabstand | HERUNTERLADEN PDF (mm) | HERUNTERLADEN PDF (inch) | |

| Диаметр (mm) | Диаметр (дюйм) | Минимальный объем сосуда | L min* Минимальное расстояние монтажа | L min** Минимальное расстояние монтажа | L max Максимальное расстояние монтажа | ЗАГРУЗКА PDF (mm) | ЗАГРУЗКА PDF (дюйм) | |

| VIGIFLAP Ø | 160 | 6“ | 0,70m3 | 4,0m | 6,0m | 17m | PDF | |

| VIGIFLAP Ø | 160 | 6“ | 1,35m3 | 3,0m | 5,0m | 17m | PDF | |

| VIGIFLAP Ø | 180 | 7“ | 0,70m3 | 4,0m | 6,0m | 17m | PDF | |

| VIGIFLAP Ø | 180 | 7“ | 1,35m3 | 3,0m | 5,0m | 17m | PDF | |

| VIGIFLAP Ø | 200 | 8“ | 1,35m3 | 4,6m | 6,6m | 17m | ||

| VIGIFLAP Ø | 250 | 10“ | 1,35m3 | 4,0m | 6,0m | 17m | ||

| VIGIFLAP Ø | 300 | 12“ | 2,90m3 | 4,6m | 6,6m | 17m | ||

| VIGIFLAP Ø | 350 | 14“ | 2,90m3 | 4,2m | 6,2m | 17m | ||

| VIGIFLAP Ø | 400 | 16“ | 4,50m3 | 5,2m | 7,2m | 17m | ||

| VIGIFLAP Ø | 450 | 18“ | 4,50m3 | 4,7m | 6,7m | 17m | ||

| VIGIFLAP Ø | 500 | 20“ | 6,05m3 | 5,8m | 7,8m | 17m | ||

| VIGIFLAP Ø | 550 | 22“ | 6,05m3 | 5,5m | 7,5m | 17m | PDF |

|

| VIGIFLAP Ø | 600 | 24“ | 7,65m3 | 7,2m | 9,2m | 17m | ||

| VIGIFLAP Ø | 650 | 26“ | 7,65m3 | 6,7m | 8,7m | 17m | ||

| VIGIFLAP Ø | 700 | 28“ | 7,65m3 | 6,4m | 8,4m | 17m | PDF | |

| VIGIFLAP Ø | 750 | 30“ | 10,00m3 | 7,3m | 9,3m | 17m | PDF | |

| VIGIFLAP Ø | 800 | 32“ | 10,00m3 | 6,9m | 8,9m | 17m |

* in posizione orizzontale:

battente mobile e spostato dal flusso d’aria in arrivo.

** Posizione verticale

Battente tenuto in posizione aperta dal sistema di molle

| Kst max | ≤250 bar.m/s |

| Kst min | Senza limiti |

| Pmax | 10 bar 145 psi |

| MIE | ≥10mJ |

| MIT | ≥400ºC ≥752ºF |

| MESG | 1,7mm 0.067inch |

| Previsione massima * | ≤ 0.5 bar |

| VIGIFLAP Resistenza | 2.0 bar |

| Marchio ATEX |  II D II D |

| Atex all'interno | Zona 20 (II 1D) |

| Polvere ** | Tutti i tipi di polveri |

| Polvere concentrazione | Senza limiti |

| Velocità del flusso d'aria | Lato aria pulita: ≤ 30 m/s Lato aria sporca: ≤ 45 m/s |

| Lavorando | Circuito aria+polvere Circuito aria pulita |

| Gamma del flusso d'aria | Tirare il flusso Spingere il flusso |

| Pressione lavorativa | 500 mbar massimo |

| Vuoto funzionante | -800mbar massimo |

| Quantità di gomito | Senza limiti |

*Vessel (potential explosion source)

**Organic dust, synthetic dust and metal dust